Your partner for

worldwide logistics

Reliable and customized forwarding solutions with over 40 years of experience – let us advise you now without obligation!

Thanks to early specialization and close cooperation, we are a leader in transports to the African continent.

You will be assigned a fixed contact person who will provide you with comprehensive advice and prompt support.

Our team works according to international standards (e.g. ISO) to ensure high quality.

Since 1981, Haalboom has stood for continuous development and customer-oriented solutions.

International logistics at the highest level

Otto Haalboom Internationale Spedition has stood for excellent transport and logistics solutions for over forty years – worldwide. Whether you are shipping your goods safely and quickly by air freight, relying on reliable sea freight capacities or planning complex heavy goods transport to Africa: we offer you flexible, safe and professional services. Thanks to our strong network, especially on the African continent, you benefit from comprehensive expertise and personal advice.

Sea freight

We take care of the transportation of your containers, general cargo or special freight. We ensure smooth processes in the port, take care of documentation and customs formalities and find the most efficient route for you.

Air freight

Benefit from fast and safe air transportation. Our proximity to Hamburg Airport guarantees short distances and enables time-critical deliveries worldwide.

Land transportation

We organize road transport in Germany, Europe and beyond. For intermodal solutions, we rely on our international network to ensure that your goods arrive efficiently and on time.

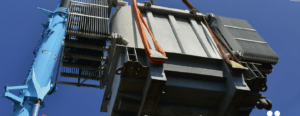

Heavy & special transports

Whether unusual dimensions or particularly heavy weights: We have the expertise to get large or heavy goods safely to their destination – anywhere in the world, of course.

Transportation of dangerous goods

When it comes to hazardous goods, safety and care are the be-all and end-all. We guarantee transportation in accordance with international safety standards and support you with documentation and handling.

Project logistics

Our experience in planning and implementing complex transportation projects makes us the ideal partner for large orders and challenging projects. We reliably coordinate all parties involved and attach great importance to transparency and communication.

Africa specialization

With fairness and patience, we have established ourselves as an international import and export specialist for all regions of Africa. Thanks to our strong network and customised solutions, your deliveries to and from Africa will run smoothly. Benefit from our in-depth knowledge of the market and our close contact with local partners.

From full containers to break-bulk and heavy transports to individual special requests, we realize all Africa transports. Talk to a HAALBOOM expert now about your projects and ideas.

- Construction site and transport machines

- Quay or solar systems

- Cars

- Canned goods and other consumer goods

Haalboom tells: Insights into our corporate world

Welcome to the heart of Haalboom! Immerse yourself in our fascinating stories and experience the milestones that have shaped our company. From inspiring moments to the latest developments – here you will find everything that makes Haalboom special.

Discover an extraordinary logistics adventure

Dear business partners and friends, In our latest project, we have redefined the boundaries of international haulage. Join us on a unique journey in which a vintage locomotive from 1981 finds its way from the picturesque landscapes of Europe to the warm ambience of the Caribbean island of St Kitts.

The end of an era

Immerse yourself in the fascinating world of international freight forwarding with the latest newsletter from Otto Haalboom. Our third issue of 2023 gives you exclusive insights behind the scenes of our diverse day-to-day work in the logistics industry. We share exciting stories, challenges and successes that characterise our daily business.

Africa – from south to north

The world of logistics is fascinating and complex. Imagine having to transport twelve lorries to Algeria, with each lorry being broken down into several parts to meet the transport requirements. Then there is the challenge of shipping custom-built Toyotas to West Africa. In this report, we take you behind the

Everyone talks, someone does it.

Logistics in action – experience how we deliver what others promise. In our media centre, we show impressive videos, pictures and stories from the real everyday life of a freight forwarder: from special transports and worldwide sea freight to personal insights behind the scenes.